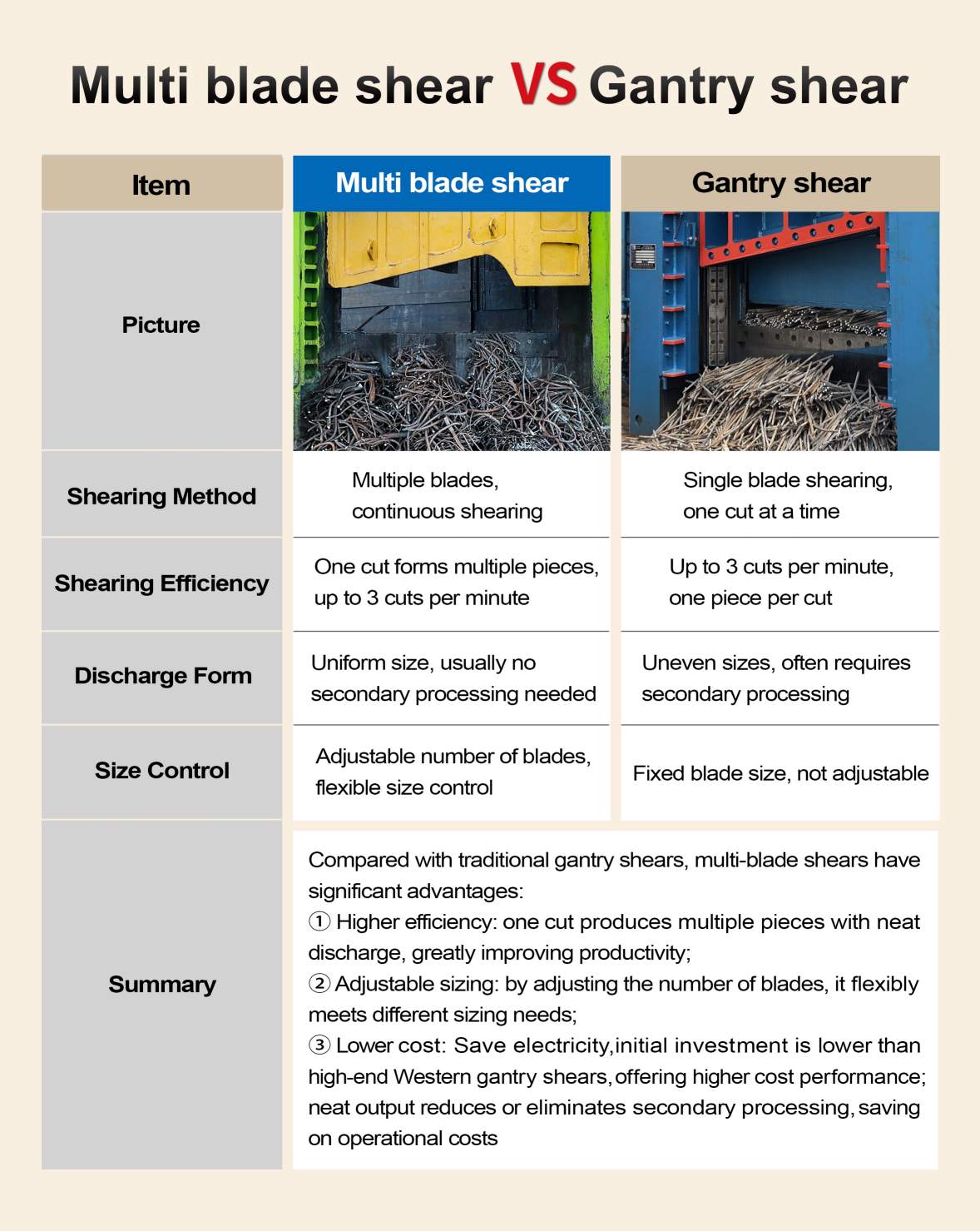

En el procesamiento de chatarra, elegir la cizalla adecuada puede tener un impacto significativo en la productividad y los costos operativos. A continuación, se presenta una breve comparación entre... Tijeras de múltiples hojas y tradicional Cizallas de pórtico:

Tijeras de múltiples hojas:Utiliza múltiples cuchillas para corte continuo: un corte crea múltiples piezas.

Cizalla de pórtico:Una sola hoja, un corte = una pieza.

La cizalla de múltiples hojas logra hasta 3 cortes por minuto, y cada corte produce varias piezas uniformes.

La cizalla de pórtico también ofrece hasta 3 cortes/min, pero con solo una pieza por corte.

Las tijeras de múltiples hojas ofrecen salida uniforme, generalmente con No es necesario ningún procesamiento secundario.

Las cizallas de pórtico a menudo producen tamaños desiguales, lo que requiere pasos adicionales.

Hoja múltiple: Cantidad de cuchillas ajustable Permite un tamaño flexible.

Pórtico: tamaño de hoja fijo, sin ajuste posible.

Mayor eficiencia – Un corte, múltiples piezas limpias

Tamaño flexible – Ajustable para cumplir con diferentes especificaciones de materiales.

Costos más bajos – Menor consumo de energía e inversión, menor tiempo de procesamiento